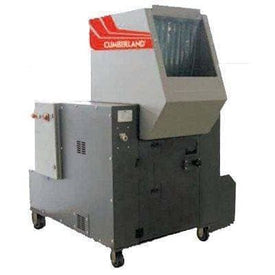

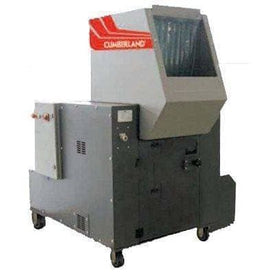

Collection: Granulators

Explore our variety of quality granulators that have multiple destruction capabilities

- Page 1 of 5

- Next page

Premium-Quality Granulators for Multipurpose Applications

When selecting our high-performance granulators, your company is guaranteed to receive a machine capable of effective data destruction. Our list of quality, government-level granulators is great for grinding scrap parts, melt delivery systems, or recycling, and is ideal for commercial businesses. Our granulators are also designed for easy maintenance, and carry a minimal risk of cross-contamination. Not the type of machine you’re looking for? Why not check out other products from Whitaker Brothers, including shredders, disintegrators, crushers, and punchers?

Granulators are mostly used for size reduction, which is an essential step if you want to recycle your plastics. They break down waste products that are inputted within the machine (such as plastic, paper, and rubber) into smaller pieces, which can then be reused for various applications.

If you are not sure about what type of machine you want, you can filter by the materials you need to be destroyed, and look for products such as solid state drives, flash media cards, and sticks.

Benefits of our Granulators

Our company provides other services than just our high-quality destruction granulators. Whitaker Brothers is a leading provider of data destruction equipment in the U.S., and our commercial-grade products are simply just one of the various services we offer.

We have been supplying state-of-the-art devices for destroying sensitive data for over 75 years, providing excellent shredders, folders, and cutters for companies across the U.S. Furthermore, our company also offers machine servicing options so our customers can routinely have their machines cleaned and maintained.

Because paper shredding can be considered non-environmental, our commitment to a greener and more sustainable business has allowed us to create our “Go Green” initiative! This means we are effectively doing our part in becoming an eco-friendly company for the planet.

You can reach our services via phone at (800) 243-9226 or fill out our “Request a Quote” page today.

FAQs

[H4] How do industrial granulators and pelletizers differ?

There is a significant difference between granulators and pelletizers in terms of their functions. Plastic pelletizers are used to chop up new plastic into pellets in order to recycle it. In contrast, industrial granulators reduce materials into granules.

[H4] What types of industrial granulators are there?

In the plastic processing industry, there are four main types of granulators. There are pressure granulators, central granulators, low-speed granulators, and shredder-granulators.

[H4] What are the basic working principles of a plastic granulator machine?

When using a plastic granulator, scrap plastic is sheared and smashed into small granules that can be molded. A rotor with heavy knives turns at a high speed near a fixed anvil. An offcut of plastic from pressed products is loaded into granulator machines usually beside the press. The larger the industrial granulator, the larger the quantities that are granulated.

[H4] How is plastic waste reduced in size?

Size reduction for plastic processors is primarily concerned with converting plastic scrap back into a size that is similar to the new or virgin material being processed. In most cases, reprocessed scrap comes in the form of sprues, runners, edge trim, or nonconforming parts.